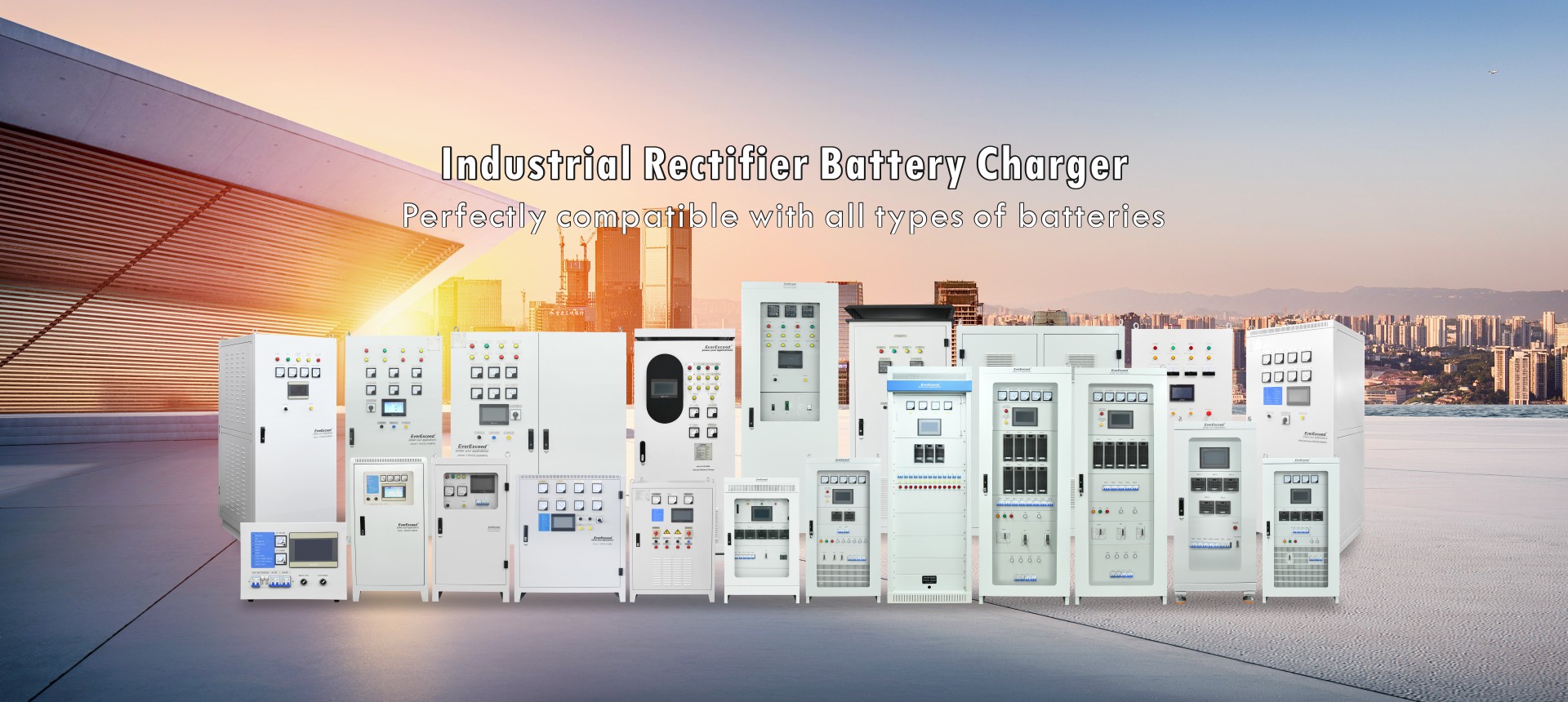

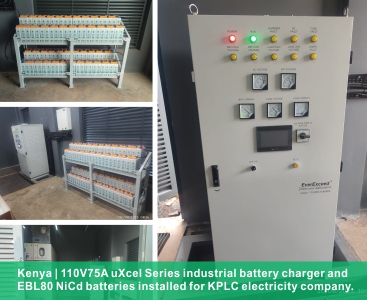

EverExceed | A global leading manufacturer of customized AC/DC power solution;

Comprehensive Industrial Chargers for Diversified DC Power Solution

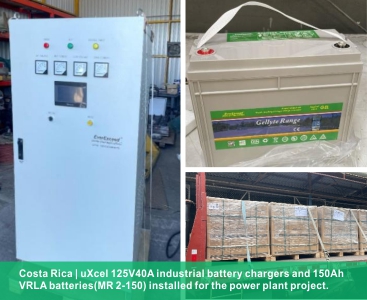

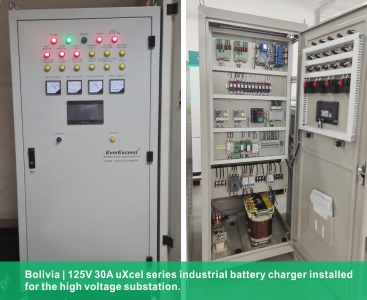

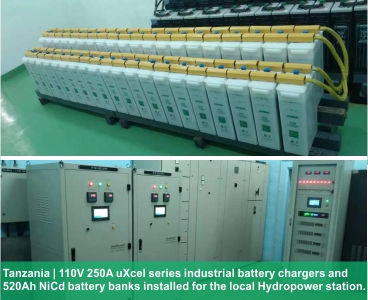

We can customize More flexible, More reliable, More stable industrial battery chargers for lead acid batteries, nickel cadmium batteries and lithium batteries.

Technical features

Large LCD display

Leading Technology

Isolation transformer

Flexible maintenance and Reduced MTTR

The design make it easy for front-access to all vital modules modules of the charger

Versatile constant voltage and constant current charging modes

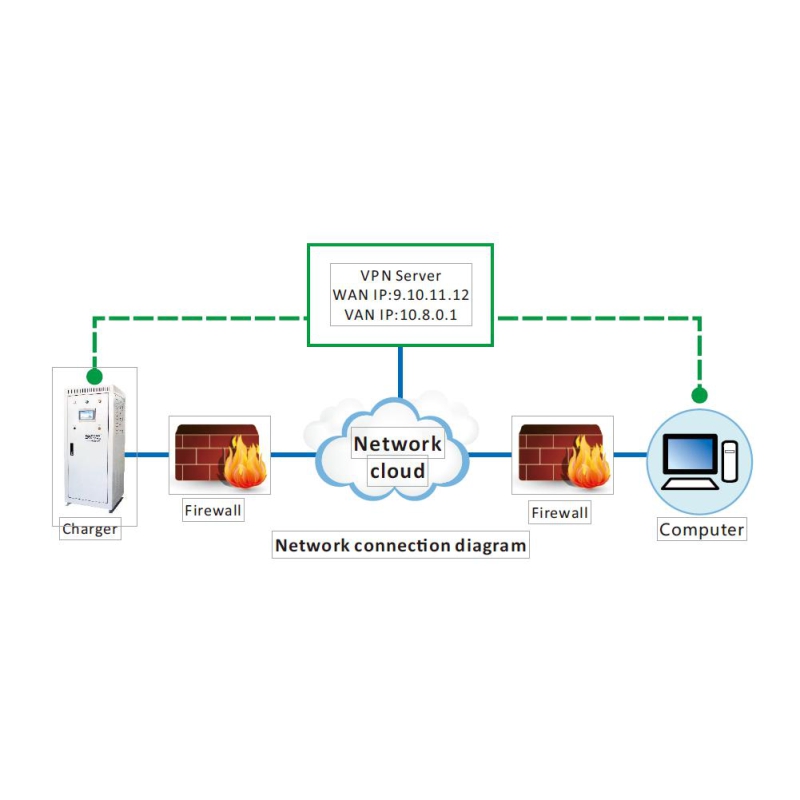

Smart communication and Remote Monitoring through isolated RS232, RS485, Ethernet. Full data logging.

Power solutions to perfectly meet the specific requirements of customer’s industrial applications.

High Reliability and High MTBF

User friendly operation with large LCD display, optional touch screen with the choices of 8 languages ensure easy maintenance and operation. Smart communication and remote monitoring.

The embedded micro-computer controller processes signals 10 times faster than standard analog methods.

Long design life up to 20+years

System design life up to 20+ years in continuous operation under the condition of appropriate maintenance.

Complete power protection solutions

To withstand harsh environments,extreme temperatures, humidity, dust and vibrations etc. Up to IP55 protection.

Including switchgear,DC distribution, monitoring suite.

Application:

The EverExceed uXcel Premium Rectifier Charger range suits all DC applications requiring a large battery back-up:

Power transmission and distribution; Continuous process industries; Oil and Gas and petrochemical industries; Transportation (rail, metro, tramway)

Our partners