1. Failure to replenish water on time: Since recharge is not 100% efficient, some recharge energy electrolyzes water molecules of the electrolyte into hydrogen and oxygen gas that exit the battery through vent caps. If neglected long enough, failure to replenish lost water causes the battery’s plates to go dry, causing permanent loss of capacity.

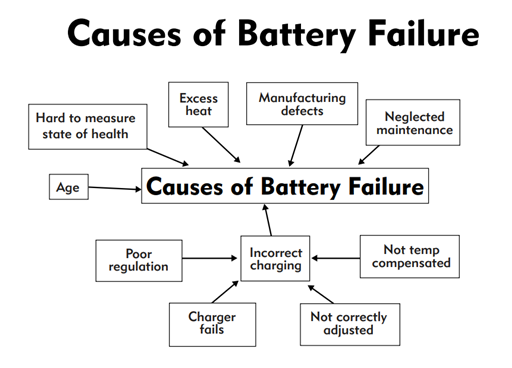

2. Incorrect charging multiplies the water replenishment problem. Some chargers run open-loop, alternately under-and overcharging the battery. Chargers with closed-loop regulation systems, but without lack battery temperature compensation, also undercharge or overcharge the battery as seasons change. Overcharging accelerates water loss. Undercharging causes sulfation with consequent permanent capacity loss. 3

3. Difficulty in assessing the battery’s state of health: The most difficult aspect of battery maintenance is that there is no simple way to measure the battery’s ability to start an engine. There is no automatic “self-diagnostic” within the battery to detect plate deterioration or partial short or open circuits. Leonidas states, “It is not sufficient to simply test the charging current to the group of batteries. The situation requires more reliable testing to evaluate each cell and replace those showing signs of degradation.” According to Cummins, “only a regular schedule of inspection and testing under load can prevent generator starting problems. Merely checking the output voltage of the batteries is not indicative of their ability to deliver adequate starting power. As batteries age, their internal resistance to current flow goes up and the only accurate measure of terminal voltage must be done under load.”

scan to wechat:everexceed