Standalone ohmic battery monitoring systems designed for data center application are not suited for a genset environment. Although ohmic monitors work, they are expensive (estimated at $2,000 for a 24-volt system), time-consuming to install, and require trained personnel to interpret their data output. To achieve widespread adoption in the genset market any battery monitoring technology will need to be low in cost, simple, functional and easy for existing service personnel to employ.

Limitations and Refinements to Midpoint Monitoring:

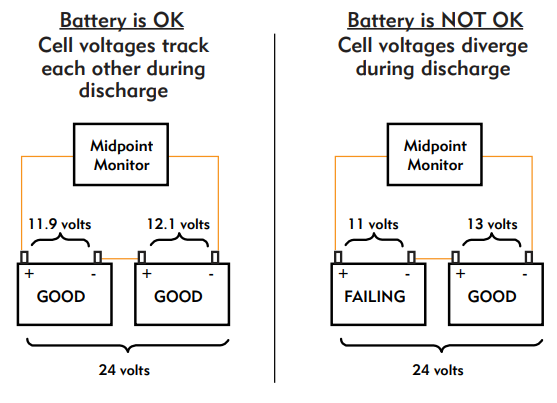

Since the midpoint monitor requires even numbers of battery blocks, it cannot be applied to 12-volt monobloc batteries. So, in 12-volt starting systems the total battery discharge voltage may be the most practical balance between performance and low cost. If the customer does not exercise his genset very often, the battery discharge voltage technique is of no value. The midpoint monitor is also of little value when the battery is on float charge because discharge stress is needed to emphasize cell-to-cell imbalance. Periodic reduction of the charger’s float voltage, however, can reveal whether the battery is able to support any connected loads and whether its halves remain in balance. This is a significant fact that influences how and where a low cost midpoint monitor should be realized.

Keeping the Solution Low in Cost and Simple:

The remaining three goals – low cost, simplicity and adaptability to the user’s environment – can be achieved only if the monitoring function is bundled into some other type of product normally supplied with the genset that contains appropriate computing and measurement resources. The product into which the battery monitoring system is integrated will need to be microprocessor controlled, contain accurate voltage measurement capability, an alarm system, a means to record data and some sort of communications capability. Battery chargers are supplied with most gensets, and have a significant advantage over the alternatives (control panel or switchgear): The battery charger controls DC voltage when the genset is not running. If the genset is not exercised regularly, the charger’s output can be changed as needed to force battery discharges for testing purposes. The charger is the only device in the genset with this capability.

24V Midpoint Monitor System compares 12V batteries to each other:

***This article is from internet, does not represent the views of this site, if there is any infringement, please contact to delete

Conclusion:

recent posts

scan to wechat:everexceed