Generally, cycle life testing will generate a lot of data, which can obtain a lot of information. What analysis and processing can we do with these cycle data? The following summarizes some of the data processing, continuation from last week’s article.

1. Constant voltage charging current and time

Lithium-ion batteries are usually discharged at different currents during use, and often cannot undergo a complete and stable discharge process. This incomplete discharge process will affect the subsequent charging process. The battery charging process is generally a cross-current-constant voltage mode CC-CV, which consists of two continuous processes: CC charging and CV charging, constant current until the battery voltage reaches the nominal maximum voltage. Subsequently, the battery enters the constant voltage charging mode, and the charging voltage remains constant until the charging current gradually decreases to the cut-off current, as shown in Figure 7. Regardless of whether the battery is completely discharged, the dynamic characteristics of the CV stage can well reflect the health information of the battery. In addition, the charging data of the CV stage can be fully monitored through the BMS. Therefore, the kinetics of CV charging can be used to study battery aging.

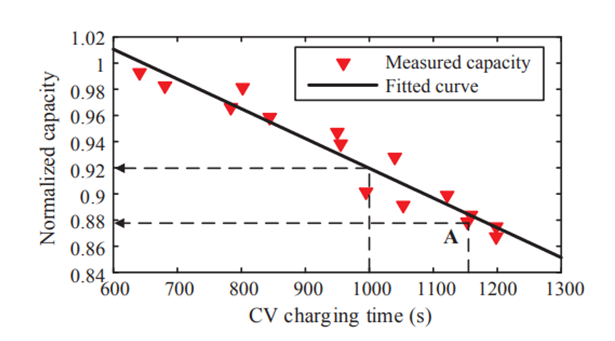

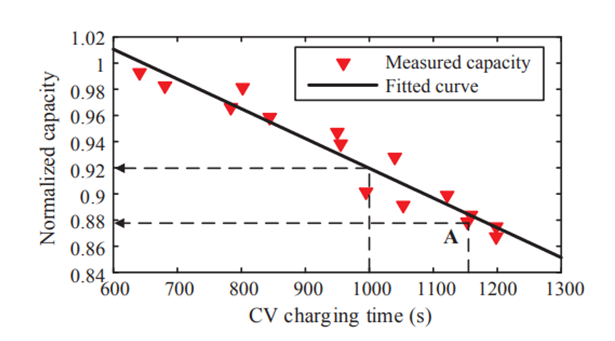

Figure 7 contains multiple CV charging current curves in different aging states. In the case of cyclic use and continuous active lithium loss, the CV charging time is affected by battery aging, and the shape of the curve is different. For example, the time required to complete the CV charging of the battery on the 30th cycle is shorter than that of the battery on the 60th cycle. In addition, the maximum curvature of the current curve decreases as the health of the battery deteriorates, and the value of the CV charging capacity between different curves is not equal. These phenomena indicate that the shape of the charging current curve in the CV charging process changes with the change of the battery SOH. For example, as shown in Figure 8, the horizontal charging time and the cycle capacity have a monotonically decreasing linear relationship, but in practical applications, some batteries cannot reach the cut-off current value due to the incomplete charging process. In addition, noise interference on the current measurement may also cause the battery to complete the CV cycle early. Compared with the complete CV charging process, either of the above two situations will affect the constant voltage charging time.

Figure 7 Constant current-constant voltage charging and discharging system and constant voltage current curve

Figure 8 Battery cycle capacity and constant current charging time CV Correlation between

5. Capacity decay curve

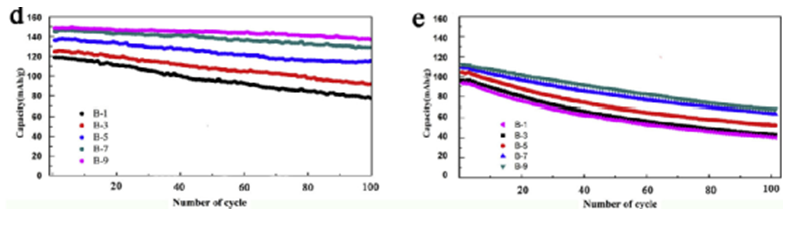

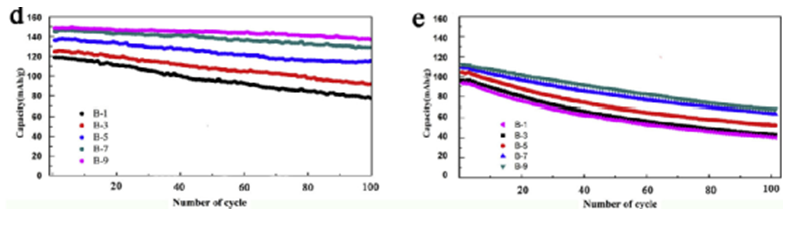

The capacity or specific capacity-cycle number curve is an important and most common characterization method for studying the failure mechanism of cathode materials, anode materials, electrolytes and batteries. The specific icons are shown in Figure 10. The detailed introduction and analysis methods are not repeated here.

Figure 10 The battery specific capacity-cycle number curve of different electrode formulations

Conclusion:

To ensure the smooth operation of your application,

EverExceed research and development engineers works day and night to research and design the state of art

Lithium Iron phosphate batteries with the perfect charging and discharging parameters which confirms the longest cycle life available for the battery. So choose EverExceed as your brand for the complete reliability.